Within our team, 9 groups work together, each with its own set of responsibilities. The coordinated efforts of these groups and our leadership have led the team to success on numerous occasions — including throughout recent competition seasons.

We created the Meet the Team concept with the goal of bringing readers closer to our groups and, through them, to our whole team. In our first professional article, Ádám Borbély, the leader of the Vehicle Dynamics group, provides deeper insight into their work by answering a few direct questions.

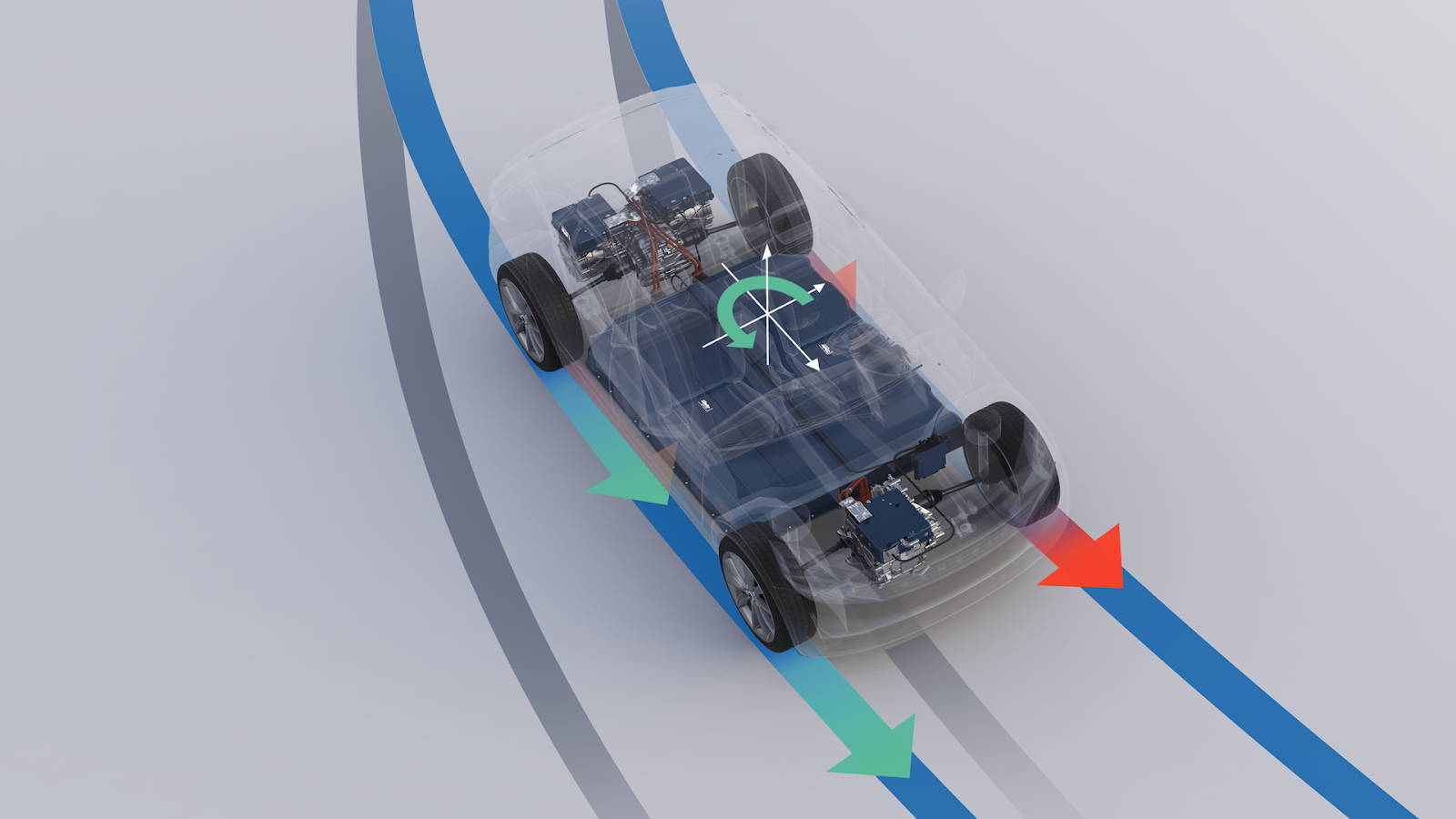

As an introduction, the main task of the Vehicle Dynamics group is the development of the program that controls the car’s all-wheel-drive system. This software has to meet several expectations: on one hand, it must ensure “optimal dynamics” — meaning it implements traction control, torque vectoring, launch control and other driver-assist functions; on the other hand, it has to efficiently utilize the potential of the electric motors.

Additional responsibilities include suspension kinematic design, suspension setup calculations, simulations examining the car’s dynamic behaviour, supervision of data recording during the spring and summer testing and competition season, as well as the analysis of this collected data.

You are developing a vehicle dynamics control software — what exactly does it do?

Ádám: In recent years of the Formula Student competition series, electric powertrains have increasingly come to the forefront compared to internal combustion engines. With electric vehicles, in-wheel motor systems have also become more widespread.

The use of in-wheel motors enables independent torque control on each wheel, which is essential for advanced torque vectoring. This technology significantly improves the car’s handling, stability, and acceleration, as it allows performance to be distributed to each wheel according to optimal traction conditions.

What new features have you prepared for this season, and what improvements were made to previous functions?

Á: The VDC (Vehicle Dynamics Control) software includes a wide range of functions. The system’s inputs come from all sensors — accelerations, vehicle yaw rate, wheel speeds, steering angle, pedal positions, and the control settings selected from the steering wheel.

Using these signals, the VDC software performs several key functions, the most important being:Longitudinal control:

The goal is to keep wheel slip within the optimal range and prevent wheelspin. With the current motors and gear ratios, we can output more than 300 Nm to each wheel, so without regulation the wheels would spin excessively, causing major time loss — especially in Acceleration and Autocross.Lateral control:

The purpose of this is to distribute torque across the four wheels in a way that increases cornering speed without compromising stability at higher speeds. This helps compensate for understeer or oversteer when needed.Power limiter:

According to the rules, the high-voltage battery may not deliver more than 80 kW of power. This is especially relevant in the Acceleration event. Ensuring that this limit is not exceeded is also part of the VDC software’s responsibilities.

This year, we focused heavily on improving the lateral controller — a complex and difficult-to-quantify challenge.

First, we must tune the vehicle’s lateral response (yaw rate or lateral acceleration) according to the driver's preference in different scenarios. This requires extensive testing and feedback, as the system is too complex to determine an objective “optimal” setting.

We achieve the desired lateral behaviour by generating additional yaw moment around the car’s vertical axis. Simply put: if we want the car to rotate more in a corner, we drive the outer wheels harder and the inner wheels less. In-wheel motors make this easy to achieve, but creating a stable, precise system requires sophisticated control algorithms.

How much time does torque vectoring save per lap?

Á: This depends heavily on the track, but since VDC helps during acceleration, braking zones, and tight corners, it always improves lap time.

On a typical Formula Student Autocross track — like the one shown below — simulations and real tests show that on a 50–55 second track, torque vectoring can provide about a 3-second improvement (~5%), which is a massive gain.

.png)

How do you develop this software?

Á: We develop the control software and most of our simulations in MATLAB/Simulink, as this environment is very well suited for solving engineering problems. Simulink is especially useful for modelling dynamic systems, running simulations, and creating control algorithms. Its block-diagram-based structure makes complex systems intuitive to visualize, while supporting MATLAB scripting and automatic code generation. This makes it widely used in industry and academia for embedded system development and testing.

This is important for our group, as new members can learn the software more easily, speeding up development.

.png)

Our development follows the V-model, meaning every function and major subsystem is tested in simulation first — since the software must work reliably even under worst-case scenarios.

Because this software determines the torque requested from the motors, it qualifies as a safety-critical system. Therefore, we generate C code from it, and it runs on a microcontroller in the car — meaning embedded systems knowledge is also required to operate it.