Meet the Team – Electric Powertrain Group

One of the cornerstones of our team’s operation is its well-structured organization: nine groups work in close coordination to ensure our race car performs at its absolute best. In the second part of our Meet the Team series, we take a deeper look into the work of the Electric Powertrain Group.

What happens beneath the carbon fiber monocoque?

How is the battery built—the one that reliably provides energy from race to race?

How can you create an energy storage system that is safe, lightweight, and high-performance all at once?

We asked Gergely Szatmári, group leader, and Kristóf Pászty, electric powertrain team member, to share their insights.

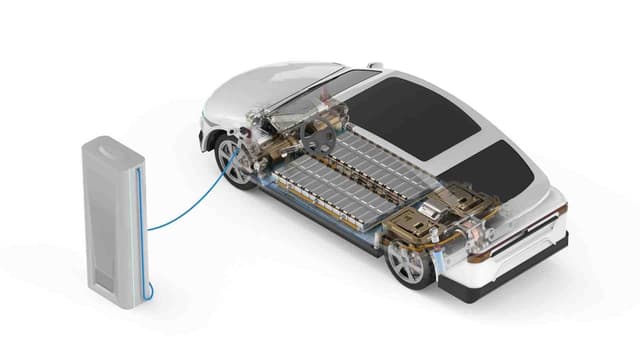

The Electric Powertrain Group is responsible for several key components: the high-voltage battery, the motor controllers, and four electric motors.

The design, development, and manufacturing of the battery are all within our scope. The only outsourced parts are the battery cells themselves—everything else is custom-designed in-house. This includes the layout of the cells, the composite battery enclosure, and the 3D-printed components that hold the cells in place. The group is also in charge of developing a custom Battery Management System (BMS).

Another key task is developing the DC-DC converter, which converts high voltage into the lower voltage required to power various systems in the car.

In addition, we are working on our own motor and motor controller development. When designing the motor controller’s housing, we placed particular emphasis on space-efficient construction and optimal placement of cooling blocks.